Discovering a Comprehensive Variety Of Mining Equipment Parts for every single Need

Wiki Article

Unveiling Important Mining Devices Components for Ideal Workflow

In the elaborate world of mining operations, the smooth performance of devices is extremely important. As we dive right into the depths of mining tools basics, a better look at the intricate information and performances of these parts reveals an interesting globe where effectiveness and integrity are the cornerstones of success.Significance of Correct Drill Bits

Appropriate option and maintenance of drill little bits are fundamental for optimizing mining efficiency and productivity (mining equipment parts). The kind of drill bit selected should straighten with the certain geological conditions of the mining site to guarantee optimum performance.Routine upkeep of drill little bits is similarly crucial to make certain durability and effectiveness. Boring or broken drill little bits can result in decreased boring speed, enhanced wear on exploration equipment, and inevitably, reduced productivity. Maintenance tasks might include developing, regrinding, or changing worn parts to maintain the drill little bits in leading functioning problem.

Secret Parts in Conveyor Equipments

Effective product transport in mining operations heavily depends on the capability and stability of essential components in conveyor systems. One crucial part is the conveyor belt itself, which lugs the materials along the mining site.

Essential Filters for Equipment Upkeep

An important element of guaranteeing the long life and optimum efficiency of mining equipment hinges on the meticulous choice and maintenance of vital filters. Filters play a crucial role in securing mining machinery from pollutants that can cause damage, bring about expensive repair work and downtime. Dust, particles, and dirt are prevalent in extracting atmospheres, making the proper filtration system important to equipment resilience.Filters in mining tools serve to trap fragments that might infiltrate sensitive components such as transmissions, hydraulics, and engines. Consistently changing these filters according to maker suggestions is vital to avoid blocking and make sure reliable operation. Disregarding filter upkeep can lead to lowered devices life-span, lowered efficiency, and enhanced gas consumption.

Important Use Parts for Crushers

In the world of mining equipment maintenance, one crucial element that requires interest is the identification and substitute of crucial wear components for crushers. Crushers play a fundamental role in the ore handling and material decrease processes within mining procedures. Several of the key wear components that are vital for the effective performance of crushers include the complying with:** Crusher Liners **: These are vital in safeguarding the crusher covering from wear and tear brought on click now by the product being crushed.

** Jaw Plates **: Established in jaw crushers, these components are accountable for squashing the product against a repaired surface.

** Mantles and Concaves **: These parts are important in gyratory crushers, where they assist in squashing the material right into a much more polished kind.

Routine assessment and replacement of these wear parts are important to ensure the crushers operate at their ideal efficiency, minimizing downtime and maximizing efficiency in mining procedures. Correct maintenance of these wear parts can significantly impact the general performance and longevity of the crushers, ultimately contributing to the success of mining tasks.

Role of Hydraulic Cyndrical Tubes in Mining

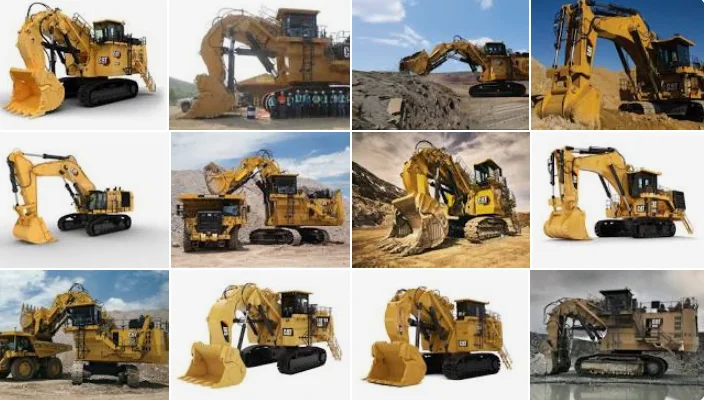

Playing a critical function in modern mining operations, hydraulic cylinders are integral parts that assist in the effective performance of various heavy equipment. These hydraulic cyndrical tubes are vital for powering necessary mining tools such as excavators, drills, loaders, and excavators.Hydraulic cyndrical tubes in mining devices are created to endure harsh operating conditions, consisting of extreme temperature levels, high pressures, and heavy loads. Their durability and dependability add to the total productivity and safety of mining operations. Proper maintenance and normal evaluation of hydraulic cylinders are vital to make sure optimum performance and avoid expensive break downs that can halt mining activities. In essence, hydraulic cylinders play an essential duty in enhancing the efficiency and performance of mining operations worldwide.

Verdict

In verdict, it is try these out important for mining operations to use proper drill little bits, vital elements in conveyor systems, critical filters for devices maintenance, necessary wear components for crushers, and hydraulic cyndrical tubes. These vital mining devices parts play a considerable function in optimizing and guaranteeing optimum procedures efficiency in the mining market. By buying top quality and trustworthy equipment components, mining business can boost performance and decrease downtime, inevitably resulting in an extra successful procedure.In the elaborate globe of mining procedures, the smooth functioning of devices is vital. By investing in remarkable purification systems and sticking to a strict upkeep timetable, mining procedures can boost equipment dependability, lessen downtime, and ultimately maximize efficiency.

In the realm of mining equipment upkeep, one essential element that requires interest is the identification and replacement of crucial wear components for crushers. These important mining equipment parts play a substantial function in maximizing and guaranteeing ideal procedures performance in the mining sector. By investing in reliable and high-grade equipment parts, mining firms can boost performance and decrease downtime, eventually leading to an extra successful operation.

Report this wiki page